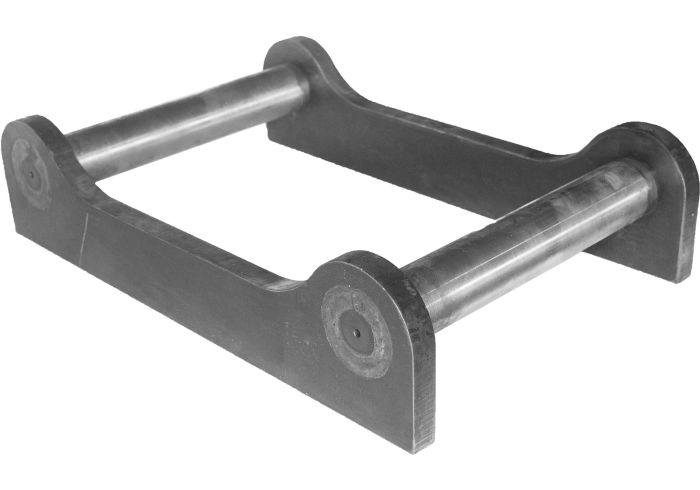

ROBUST S-system Mounting brackets for quick couplers

- ROBUST S-system Mounting brackets defined by the machine suppliers.

- Indicates the diameter of the axles in mm.

- Complete assortment from S30/150 to S120.

Variations

Partrex mounting brackets ROBUST™ are smartly designed to be maximally stable.

An S-system Mounting brackets shall be stable, correctly dimensioned and symmetrically constructed. An oblique or unstable mounting bracket can damage both the attachment to the machine and the tilitrotator if you have one. The mounting bracket shall meet the Machine Suppliers' standard for the dimensions of symmetrical S-system mounting brackets. ROBUST mounting brackets does that and more.

ROBUST™ mounting brackets with Guaranteed Stable™ construction

Axles in ROBUST mounting brackets is made of selected machine axle steel in the right quality, C45/SS1650. They are lathed down at the ends so that the axle self-locks the side parts in the inward line, which makes them guaranteed to be dimensionally stable. This is in contrast to mounting brackets with axles that run freely in the side parts and are only attached with the weld at the end. The side pieces are made of strong 355 structural steel and provides perfect and stable fitting of the countersink axle ends. On the outside, where the axle ends and side parts are joined, are the holes in the side pieces and the ends of the axles bevelled to provide a strong (and hidden) weld. Overall, this makes the ROBUST mounting brackets very stable.

To achieve additional stability between the mounting bracket and the implement, you can weld in support against the side pieces towards the ends of the axles. Side supports in combination with the self-locking axles on the inside provides a very stable mounting bracket.

Facts: S-system Mounting brackets

The S standard has been prepared by the Swedish industry organization Maskinleverantörerna. The standard simplifies the supply of tools to the machines. An additional advantage of the S standard is that the wedge-based fastening construction provides high safety compared to many other mounting brackets. Low construction height and low weight are additional advantages. The S-system mounting bracket is basically maintenance-free.